Features and Design

Features

Courtesy of Thermalright

- TS use the principle of Heat pipe direct touch, provides seamless thermal conduction between the heat sink and CPU.

- Aluminum heat sinks with our latest design to accelerate airflow to increase the efficiency of the fan.

- Offset base for better VGA card and memory clearance.

- The Best C/P CPU Cooler for Overclockers & Gamer !

- Black top to complement build aesthetics and heat pipes nickel plated.

- Including one Thermalright TY-140 Black Utra-low noise 300~1300RPM PWM-Fan (MAX21 dBA).

- Fan-clips are compatible with both 140mm and 120mm fan.

- Multiple support bracket system For Intel and AMD platform.

Cooler Design

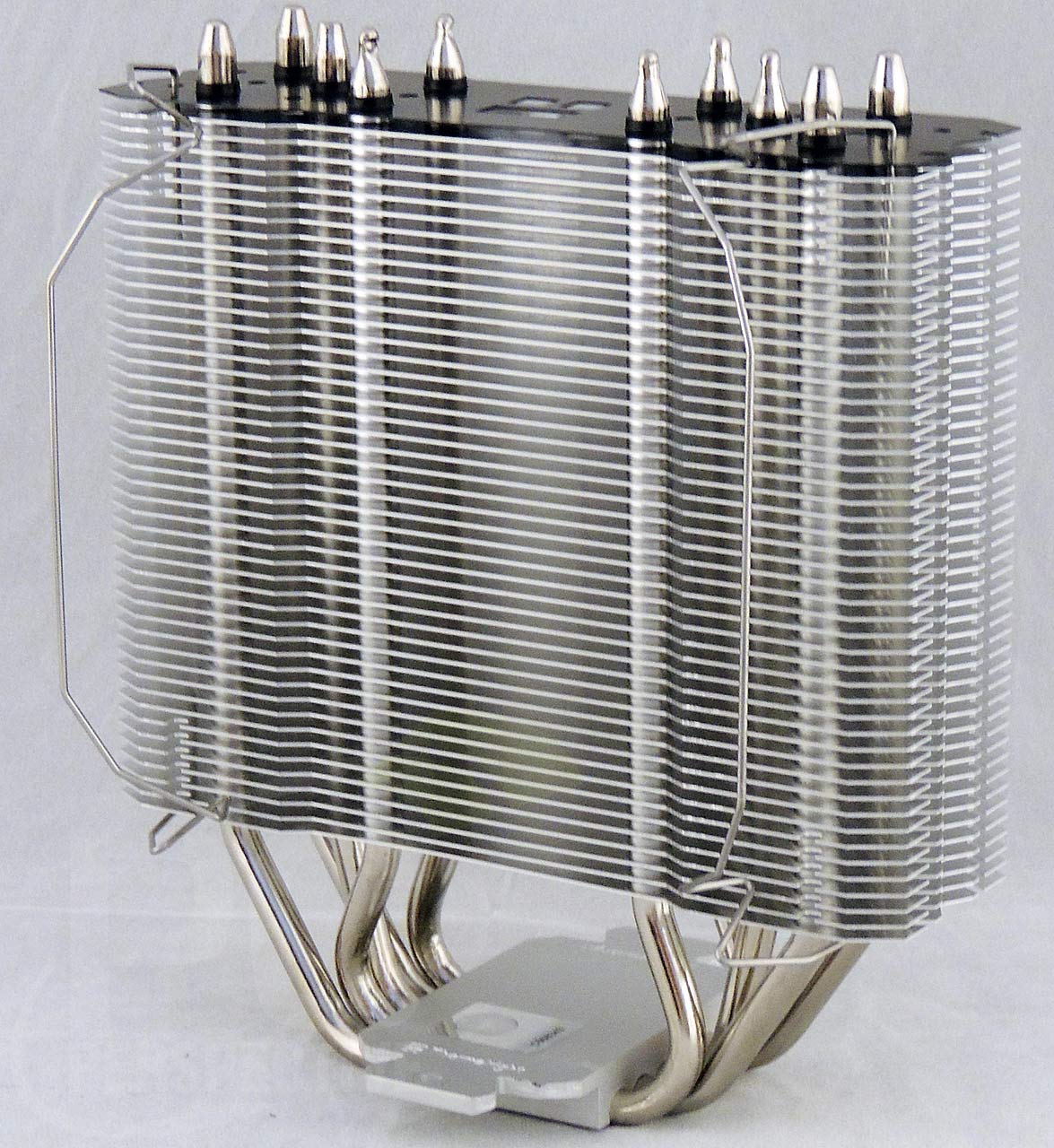

The Thermalright TRUE Spirit 140 Direct CPU cooler is a single tower, dual metal design with five 6mm heat pipes for heat transfer. The heat pipes are constructed of nickel-plated copper to optimize heat absorption from the CPU and transfer to the aluminum radiator fins for dispersal. The nickel plating also gives the copper pipes protection form the elements, preventing the copper from oxidizing. The cooler supports dual fans in a push-pull configuration, but comes standard with a single 140mm fan.

Thermalright designed the rectangular radiator with an 11 fpi (fins per inch) density, maximizing the airflow potential through the tower while minimizing fan power needed for effect air traversal. The fins are bonded to the heat pipes on each level, giving the structure added stability and rigidity, as well as ensuring a solid hand-off medium between the two structures. Heat passes from the CPU into the center of the heat pipes and then travels up each side of the U-structure to be passed to the aluminum radiator and dispersed via the air flowing through the tower. The CPU contact plate is a solid aluminum part with the heat pipes pressed into it for a snug fit. On either side of the base plate are mount holes for securing the base plate to the CPU. The five heat pipes are aligned in two sets of five along both sides of the base plate with in an X configuration – two along either side and one in the middle. This ensures that heat is evenly distributed along the entire plane of the radiator's aluminum fin "levels".

From the side view, you can more easily see the minimal width of the radiator tower, barely thicker than 2x that of a normal fan's width. The fan sits over the base plate's mount holes when mounted to the radiator, requiring removal and reattachment when trying to mount or remove the cooler from the motherboard. The side view also gives a better visual of the heat pipe layout coming from the base plate into the radiator tower.

The top-down view of the cooler gives a further look at the X-type arrangement of the heat pipes along both sides of the radiator. Both ends of the heat pipes are sealed, capped, and bonded to the radiator's top plate. Note that the top plate is a black non-metallic layer. Also, Thermalright chose to put a cutout of their corporate logo in the exact center of the cooler, going through all layers for an interesting effect.

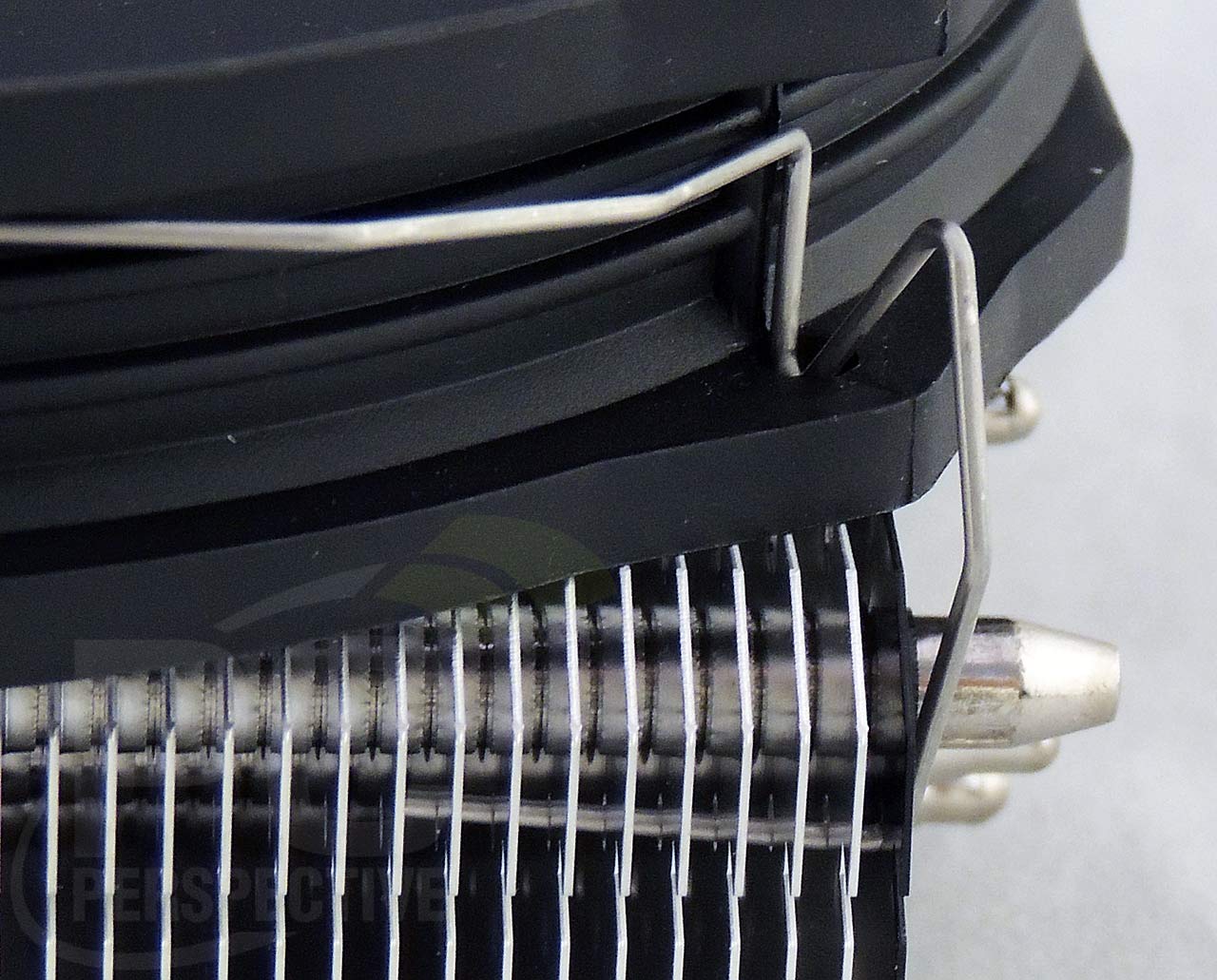

Thermalright's fan mounts are a bit different then I've seen on other coolers, but seem to be more secure and less invasive to the radiator structure. The fan mounts fit into holes through the radiator along the front and back left/right edges, using the radiator's structure for support. The fans then snap into the mounts with triangular sections fitting into the fan mount holes. The fans mounts are formed to fit around the inside of the fan housing for a snug fit between the fan and the mount to hold it securely against the radiator.

The cooler easily accommodates dual fan mounting with fan mount holes provided to accommodate fan's on both sides of the radiator tower.

The contact area for the CPU consists of the bare heat pipes press-fit into the base plate, flattened and sanded smoother for a uniform contact area. There are gaps between the heat pipes, but the surface formed by the flattened heat pipes was flattened evenly in the manufacturing process to ensure uniform contact with the CPU surface. This is further proven by the uniform thermal paste spread shown on the CPU. If there was any variation in height between the heat pipes, there would be major gaps in the paste spread pattern. However, care must be taken on spreading the thermal paste along the bottom of the cooler to ensure good contact.

link on the main page leads

link on the main page leads to pcper main page, not to the article

Fixed, thanks for pointing

Fixed, thanks for pointing that out…

thanks for the

thanks for the review

relatively small footprint and stands up very well against the mighty Noctua, so definitely going on my list of parts to consider for future builds

and it has ryzen support, awesome

At the bottom of the

At the bottom of the ‘Features and Design’ page:

‘If their was any variation in height between the heat pipes…’

Under ‘Included Accessories’:

‘The socket top is then put on top of the CPU / space plate adn locked in place.’

At the top of the ‘Conclusion’ page:

‘… impressive peice of kit…’

In the middle of the ‘Conclusion’ page:

‘…small single tower radistor…’

Also, you spell ‘upper-most’ with a hyphen, but ‘innermost’ without one. I don’t know which spelling is correct, but surely you should at least be consistent.

Thank you for the feedback,

Thank you for the feedback, this has all been corrected…

one hell of a review. i

one hell of a review. i usually would look passed thermalright, and would focus on enermax, coolermaster and deepcool. i may consider getting one for my ryzen 5 1600.

Thermalright have been around

Thermalright have been around for a long time, way before Noctua became popular.

I am still using my first Thermalright that i had mounted on my AMD 6400+ , just had to buy a different mounting kit for socket 1151 when i upgraded. it is a Thermalright Ultra 120 Extreme and its been in use for almost 10 years now ,replaced the fan about 3 times so far and have a Noctua fan on it right now.

I considered buying the True

I considered buying the True Spirit Direct for my personal Ryzen 1800x build, but opted for the larger True Spirit Power with the 8mm pipes, simply because I was curious and have a big enough case. Thermalright’s site rates the 140 Power at 325 watts, but don’t seem to have a rating for the 140 Direct. That’s a lot of watts, I wonder if it would handle the new Intel X299 chips. (?)

The Power is intended for a big case, it’s over 171mm tall and weighs 725 grams vs 161mm and 650 grams for the Direct. Honestly, the Power is overkill for the 1800x which runs cool no matter what I do to it. The Direct would have saved me $10, and kept it almost as cool.

I like the True Spirit series. They have great performance and are very space efficient. They are well built and look really good. Their fans seem to be excellent.

IMHO Thermalright is the Rolls Royce of air coolers. All four of our family computers are equipped with Thermalright coolers. I have a box full of old Thermalright video card and CPU coolers that I would like to use some day; these coolers seem to last forever.

I personally am a big fan of

I personally am a big fan of their Macho series, although they are huge. But you must believe me, they’re great coolers, and nobody does them as good as they do.

what are your temps at with

what are your temps at with that cooler?